At Behrends Foundry, the plaques we make are the result of a collaborative effort – from the first preliminary consultations and designs to the final installation of the piece, our team of professionals works closely together in order to ensure that excellence and expertise permeate every step of the process. Below is a detailed account of the bronze casting process so you can see for yourself the importance of each and every team member, here at Behrends.

STEPS IN THE LIFE OF A PLAQUE

CONSULTATION AND DESIGN

In a world with endless possibilities, creating the perfect look for a plaque is both invigorating and challenging. Capturing the exact essence of the plaque’s purpose requires a strong attention to detail and expertise in the visual arts. Behrends’ designers boast impressive resumes – with years of experience and exceptional talent, they prides themselves on crafting perfect lasting impressions. Our use of only the best technology to create renderings for our clients allows them to envision their plaques in the environments they will be manufactured for and this adds to the whole creative experience.

PATTERN

Once a design is created, the process of casting the bronze begins. The first step in the process is the creation of a pattern – a prototype of what will eventually be made in bronze. These can be made of various materials, such as photopolymer resins, woods and plastics. Behrends also use a variety of software for 3D machining and 3D printing for the more complicated shapes that may be required for the pattern process. The pattern makers at Behrends have been in the industry for decades and pay extraordinarily close attention to the details in this critical part of the process. What we find in the pattern, will likely appear in the final product so a craftsperson’s hands have to be skilled.

MOLD

The pattern, once complete, can then be used to create a mold for the final product. First, the molder applies a layer of mold release to the pattern so that the finished mold will not stick to it. Then a fine sand/epoxy mixture is applied and packed down over the entire surface of the pattern to ensure all the fine details are included in the mold. The mold is then reinforced so that it is sturdy enough to maintain its integrity throughout the casting process.

METAL POUR

Filling the mold with molten bronze is not a simple task – workers have to be incredibly careful while handling the hot metal, and processes must be in place to eliminate air bubbles while it is poured. In order to safely and effectively fill the mold: sprues, runners, gates and risers are used to introduce the bronze to the mold and they also act as ventilators, letting mold gases to escape. If you have ever been fortunate enough to see a traditional metal pour, you will notice our team members are wearing protective gear that looks a lot like space suits! As futuristic as it seems, bronze casting is actually an ancient tradition.

MOLD SHAKE-OUT

After the bronze has cooled and solidified, it has to be removed from its casing. Team members do this by shaking the mold to loosen all of the sand from the plaque. This process safely removes the sand from the bronze, leaving the rough cast plaque ready for the final touches.

FINISHING

Finishing the metal plaque involves a number of important processes and has to be done by someone with a perfectionist’s eye. All of the components used in the crafting of the plaque that will not be part of the finished product – such as sprues, runners, and gates – must be removed. The bronze is then hand-cleaned and sanded to give the piece a perfect shape and finish.

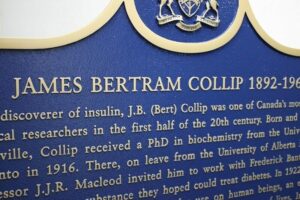

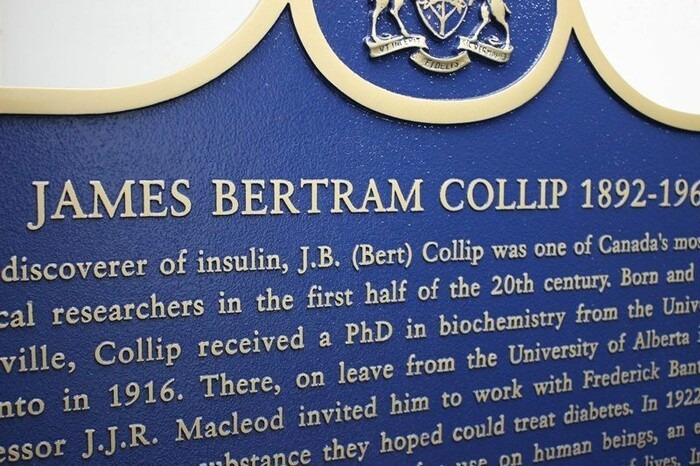

PAINTING

To put the final visual touches on the piece, bronze plaques are painted using an industrial paint system. A steady hand and attention to detail makes this finishing process the final touch at the end of the life of a plaque. Talented craftspeople do the painting to give the plaque further dimension, character, and personality as well as keep it well protected.

INSTALLATION

The final step in the process comes when a talented team of installers takes the carefully made bronze plaque and expertly installs it in its forever home. At Behrends, our plaques might end up high in the sky or amongst busy foot traffic, and either way they need to be there to last: the perfect installation completes the life cycle of a plaque and is just as essential to get right as ever other stage of the process.

At Behrends Group, when our talented foundry artisans work together, beautiful things happen!

Contact us today to discuss your next plaque project.